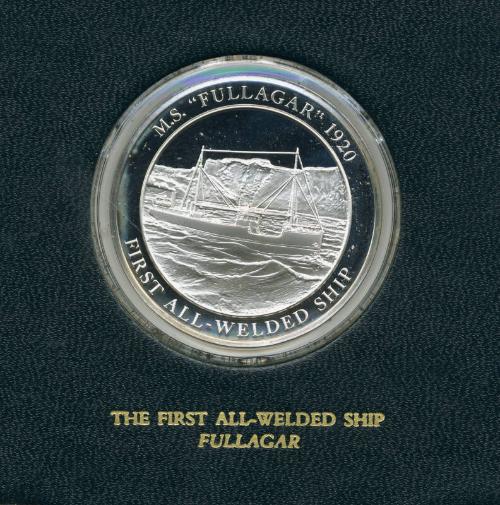

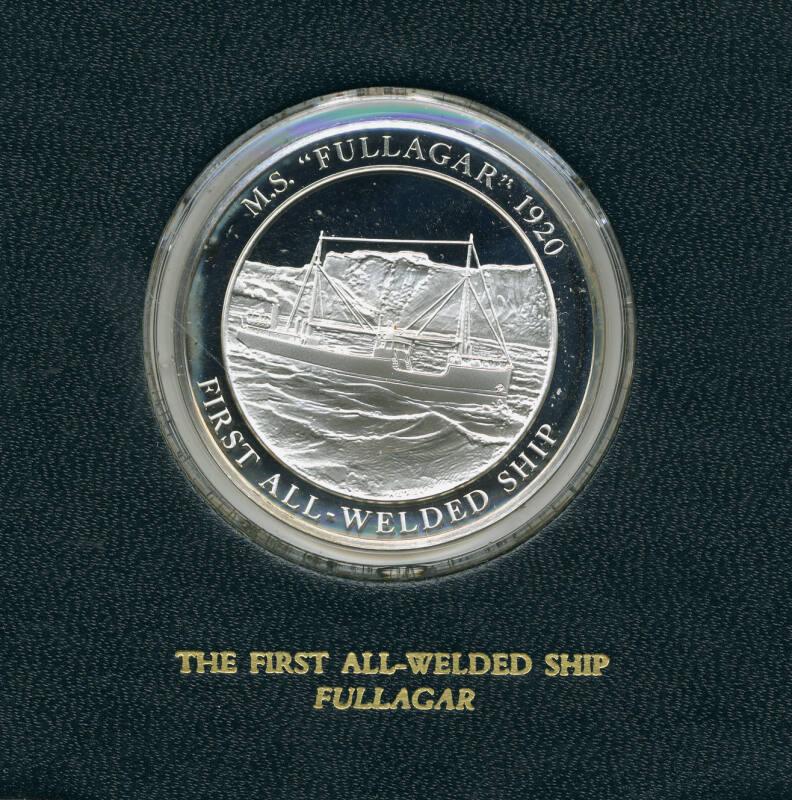

Mountbatten Medallic History of Great Britain and the Sea Medal: The first All-welded ship Fullagar

AssociatedAssociated with

Lord Mountbatten of Burma

(Frogmore House, Windsor, England, 1900 - 1979)

Medallist

John Pinches, Medallists

DateMay 2004

Object NameMedal

MediumSterling Silver

ClassificationsMedals

LocationView by Appointment - Aberdeen Treasure Hub

Object numberABDMS072500.87

Keywords

It was not until after the First World War, however, that welding was exclusively applied to the construction of a sea-going ship. The vessel so built was Fullagar, designed and constructed by the Birkenhead shipbuilding firm of Cammell Laird and Company not to a

special order, but as a speculation. She was completed in 1920 and was of a conventional design, intended for service in the coasting and short-sea trades. She measured 150 feet in length, 23.7 feet in breadth, and had a depth of just over 10 feet, giving her a gross of 398 tons. She was approved by Lloyd's Register of Shipping and met their '100 A.1' class, but she was subject to an annual survey as an 'experimental' vessel.

Her welded construction was not the only novel feature of the ship. She was named after H.F. Fullagar, who, between 1913 and 1914 had developed and patented a new kind of diesel engine; this novel design was subsequently taken up by Cammell Laird's and adapted by them for the purpose of marine propulsion. It was this association that gave Fullagar her name.

The vessel was regarded as a considerable success. This was demonstrated particularly -when she went aground in 1924: despite the fact that many plates were bent, none was fractured, and the welding techniques had withstood their first real test. By this time Cammell Laird had sold Fullagar to the celebrated shipowning firm of T. & J. Brocklebank of Liverpool, who in turn had sold her to other British buyers. The vessel survived until 1937 when she was lost by collision whilst under the Mexican flag as the Cedros.

Welding had several advantages: it permitted a reduction in the weight of hulls, with a consequent increase in carrying capacity, and it also encouraged prefabrication, which simplified and speeded up the whole process of shipbuilding. Despite these considerations, shipbuilders were slow to adopt these new techniques, and welding came into its own during the Second World War when it was unquestionably one of the main factors permitting the Allies to maintain the size of their merchant fleets despite huge wartime shipping losses. The development of welding played no little part in the successful outcome of the war, since, without seaborne supplies conveyed in standardized and quickly built ships, taking full advantage of prefabrication, Britain could not have emerged victorious.

The Mountbatten Medallic History of Great Britain and the Sea, John Pinches Medallists Ltd.

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004

Lord Mountbatten of Burma

May 2004